Correct shaft length - if the club is

too long for the golfers ability, it will mean an increase in off centre hits,

resulting in loss of directional control and a substantial loss

in distance.

Flex is not the only shaft variant to consider; every shaft type has its own torque and bend point characteristics, not forgetting balance point. Particularly true when it comes to the huge number of graphite shaft options out there. Choose the wrong characteristics for your swing and you could struggle getting the ball off the ground, or launching it into orbit amongst other things.

When tested, the average golfer increases their club head speed by a mere 2mph when using a 45" driver over that of a 43" driver; but, when they fail to hit the centre of the golf club (and they will) due to the extra length the lost distance will be dramatic. The average golfer will hit a longer ball down the middle of the fairway with a 45" driver than he would with a 45.75" driver that most manufactures produce. It is FACT that Tiger Woods has used a 43" driver to win most of his Major titles and the average driver length on the PGA Tour is less than 45.5". So, why do pro shops and golf stores fill their shelves with drivers of lengths in excess of 45"? And why do we buy and expect to control a driver length a tour pro won't carry in his bag? The answer is simple, clever marketing from the big manufactures and the average golfer failing to resist the temptation of another 2 or 3yds from the tee, which will never materialise.You may be longer to the left or to the right, but consistently down the middle is not usually an option. Why not rather get a shaft fitted for you that will give you maximum distance and accuracy for your swing.

Steel shafts by the nature of their construction are usually heavier than graphite and for this reason they're often the first choice for the irons of the stronger golfer or golfers with faster swing tempos. They also have the benefit of being more consistent than graphite. But graphite technology has excelled at a rapid rate in the last few years and now are really worth considering and can aid many people to a great extent.

A shaft with a little more flex than you need, will give you more distance, but less accuracy, if a shaft has a little less flex than you need, the reverse will apply.

It is universally agreed that there is no standard within the golf industry for governing shaft stiffness or flex. One company's stiff flex shaft may well be another company's regular flex. Depending on the shaft's restrictive characteristics and the orientation of the spines the same flex shaft will play as a regular flex in one position and as a stiff in another. Likewise comparing a different manufacture it may be a senior flex and elsewhere even a ladies flex.

Graphite shafts are lighter than steel, this helps the golfers with slow swing speeds increase their club head speed, hitting the ball further. Conversely graphite shafts can be made extremely stiff with very little shaft torque, a must for the big hitters capable of overpowering a stiff steel driver shaft.

Graphite shafts are kinder on hands and arms; they don't transmit the shock of impact of steel shafts. Good news for people suffering with problems like arthritis and tennis elbow.

But there are grips designed to take the shock that could also be a solution.

We carry a vast range of steel and graphite shafts from Nippon, Irod, UST V2, Proforce, as well as Graphite Design, Aldila, Grafalloy, True Temper, etc for ladies and gents of all ages and abilities. As we are all different we all have different requirements for shafts, so one that works for a tour player is unlikely to work for you, and one that works for you is unlikely to work as well or at all for your friend. One shaft company's regular is another's stiff. Most companies offer very little choice for ladies, see if we can offer more. For even greater distance we optimise can optimise the shaft for maximum performance and find a ball that works best (from all manufacturers not just one brand) with your driver without compromising your putting feel. Correct length, lie and loft, and shaft are also extremely important with iron play. We ensure correct gapping of irons and distance and dispersion control. Grip condition and size can adversely effect the direction of the ball and loss of feel off the club at impact as can swing weight.

When building clubs one can either assemble a club in the same manner as is used on an assembly line or build it in such a way that the shaft performs at its optimum thus allowing the head to impact the ball perfectly. There are many names for this process, pureing, spining, spine aligned, splining, or use a series of processes, like we do for maximum benefit.

in distance.

Flex is not the only shaft variant to consider; every shaft type has its own torque and bend point characteristics, not forgetting balance point. Particularly true when it comes to the huge number of graphite shaft options out there. Choose the wrong characteristics for your swing and you could struggle getting the ball off the ground, or launching it into orbit amongst other things.

When tested, the average golfer increases their club head speed by a mere 2mph when using a 45" driver over that of a 43" driver; but, when they fail to hit the centre of the golf club (and they will) due to the extra length the lost distance will be dramatic. The average golfer will hit a longer ball down the middle of the fairway with a 45" driver than he would with a 45.75" driver that most manufactures produce. It is FACT that Tiger Woods has used a 43" driver to win most of his Major titles and the average driver length on the PGA Tour is less than 45.5". So, why do pro shops and golf stores fill their shelves with drivers of lengths in excess of 45"? And why do we buy and expect to control a driver length a tour pro won't carry in his bag? The answer is simple, clever marketing from the big manufactures and the average golfer failing to resist the temptation of another 2 or 3yds from the tee, which will never materialise.You may be longer to the left or to the right, but consistently down the middle is not usually an option. Why not rather get a shaft fitted for you that will give you maximum distance and accuracy for your swing.

Steel shafts by the nature of their construction are usually heavier than graphite and for this reason they're often the first choice for the irons of the stronger golfer or golfers with faster swing tempos. They also have the benefit of being more consistent than graphite. But graphite technology has excelled at a rapid rate in the last few years and now are really worth considering and can aid many people to a great extent.

A shaft with a little more flex than you need, will give you more distance, but less accuracy, if a shaft has a little less flex than you need, the reverse will apply.

It is universally agreed that there is no standard within the golf industry for governing shaft stiffness or flex. One company's stiff flex shaft may well be another company's regular flex. Depending on the shaft's restrictive characteristics and the orientation of the spines the same flex shaft will play as a regular flex in one position and as a stiff in another. Likewise comparing a different manufacture it may be a senior flex and elsewhere even a ladies flex.

Graphite shafts are lighter than steel, this helps the golfers with slow swing speeds increase their club head speed, hitting the ball further. Conversely graphite shafts can be made extremely stiff with very little shaft torque, a must for the big hitters capable of overpowering a stiff steel driver shaft.

Graphite shafts are kinder on hands and arms; they don't transmit the shock of impact of steel shafts. Good news for people suffering with problems like arthritis and tennis elbow.

But there are grips designed to take the shock that could also be a solution.

We carry a vast range of steel and graphite shafts from Nippon, Irod, UST V2, Proforce, as well as Graphite Design, Aldila, Grafalloy, True Temper, etc for ladies and gents of all ages and abilities. As we are all different we all have different requirements for shafts, so one that works for a tour player is unlikely to work for you, and one that works for you is unlikely to work as well or at all for your friend. One shaft company's regular is another's stiff. Most companies offer very little choice for ladies, see if we can offer more. For even greater distance we optimise can optimise the shaft for maximum performance and find a ball that works best (from all manufacturers not just one brand) with your driver without compromising your putting feel. Correct length, lie and loft, and shaft are also extremely important with iron play. We ensure correct gapping of irons and distance and dispersion control. Grip condition and size can adversely effect the direction of the ball and loss of feel off the club at impact as can swing weight.

When building clubs one can either assemble a club in the same manner as is used on an assembly line or build it in such a way that the shaft performs at its optimum thus allowing the head to impact the ball perfectly. There are many names for this process, pureing, spining, spine aligned, splining, or use a series of processes, like we do for maximum benefit.

Commercial brands offer custom build, that means you may have a choice of shafts fitted that are not pre assembled for regular shop supply, but mostly only assembled on request so that requested length adjustments can be made, before fitting a requested grip with the requested number of layers of tape under the grip to increase the grip size. They are assembled in the same manner as is used on an assembly line. Each brand has a range of shafts to select from, but they do not take into account what the shaft properties are, merely set the shaft to where the label is placed on the shaft.

CUSTOM BUILT CLUBS

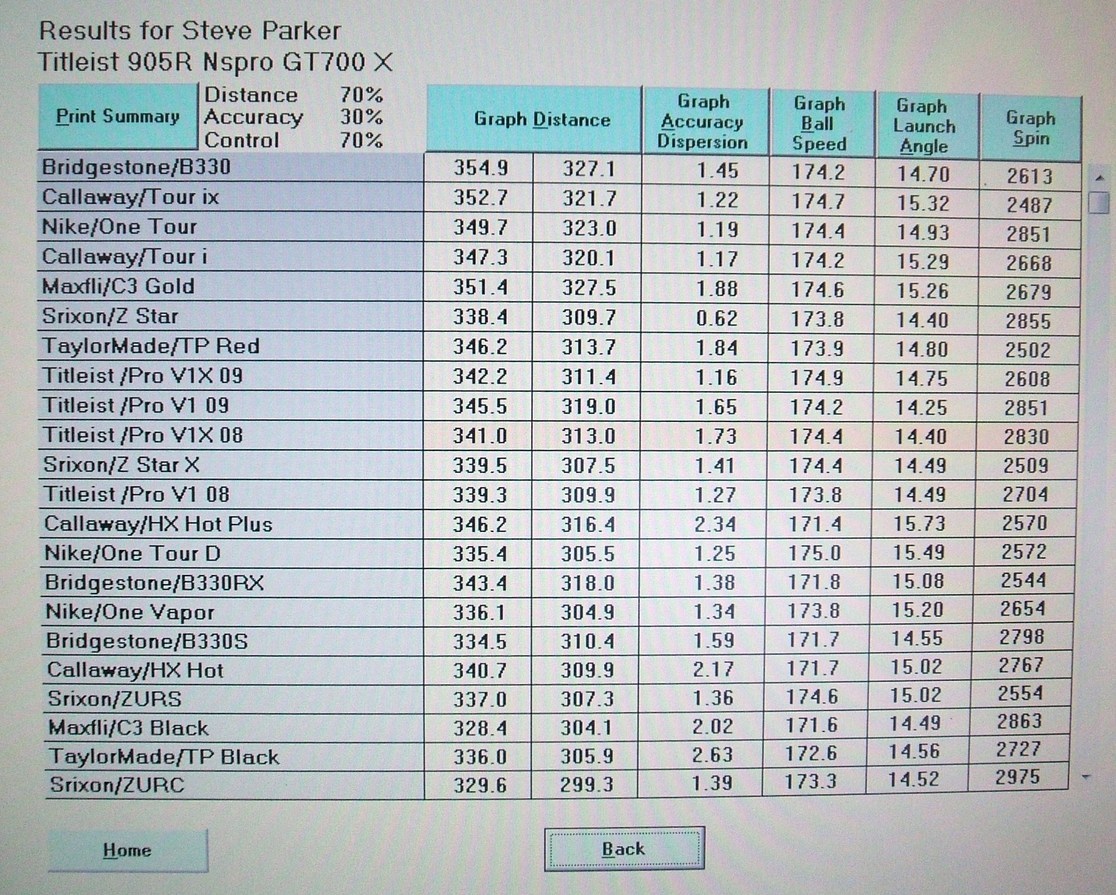

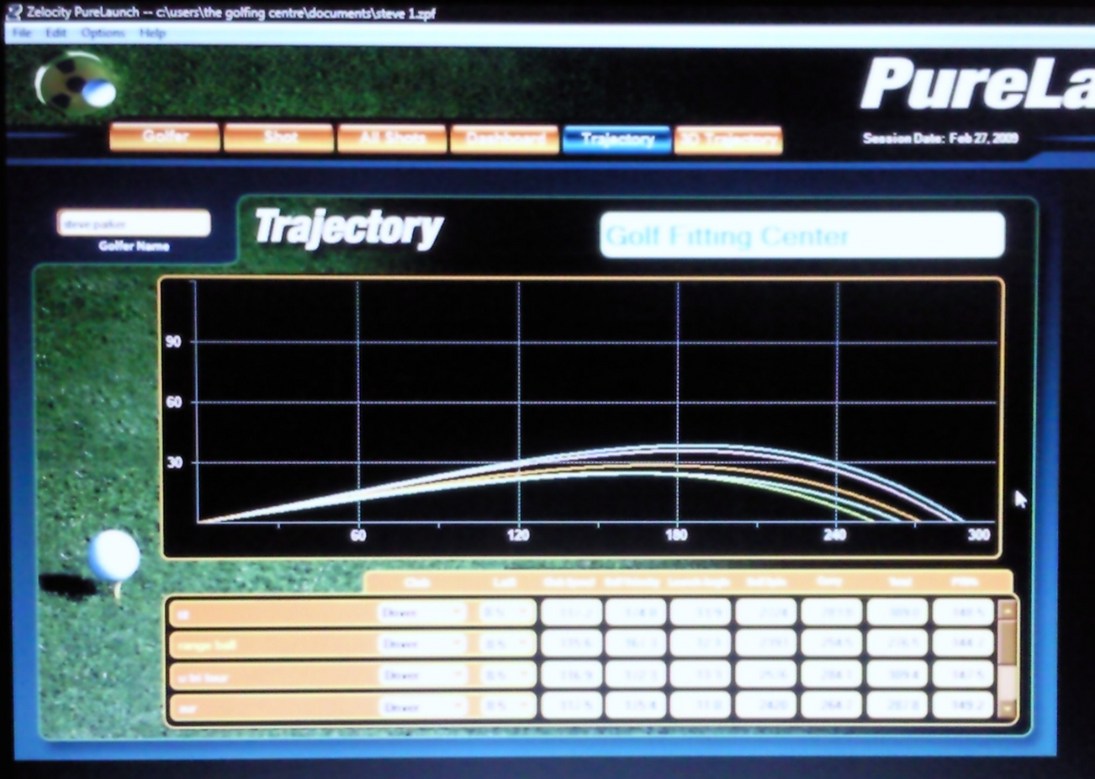

Bespoke custom built clubs are what sets clubs apart from all other. The components are preferably selected as a result of a fitting using a radar launch monitor by a properly trained fitter who knows how to interpret the information provided. We run this data through other software where we can study additional scenarios created when optimising various aspects of the data. Our choice is to fit outdoors where it is possible to see the results thus verifying the ball trajectory and ensuring that the ball does not run out of spin at the end of the flight. It also eliminates results caused by bad alignment of the golfer or a bad swing. Verification is essential for both fitter and golfer. The golfer can see the results in reality, not just pictorial or numbers on a screen that he does not understand, but the fitter can use to explain why the visual results are that way.

Bespoke custom built clubs are what sets clubs apart from all other. The components are preferably selected as a result of a fitting using a radar launch monitor by a properly trained fitter who knows how to interpret the information provided. We run this data through other software where we can study additional scenarios created when optimising various aspects of the data. Our choice is to fit outdoors where it is possible to see the results thus verifying the ball trajectory and ensuring that the ball does not run out of spin at the end of the flight. It also eliminates results caused by bad alignment of the golfer or a bad swing. Verification is essential for both fitter and golfer. The golfer can see the results in reality, not just pictorial or numbers on a screen that he does not understand, but the fitter can use to explain why the visual results are that way.

Our design engineering and computer backgrounds (over 30 years combined experience and university educations) and professional golf tour and teaching experience and knowledge has massive advantage, over and above the studying necessary after completing the very basic club making and fitting courses available in UK. These basic courses are mainly offered by larger component suppliers, whose interest is in the sale of components, and are not sufficient to set up business. These trainers have little or no technical knowledge of the thousands of shafts now available. The shaft industry is massive with enormous technical advancement and huge implication to fitting, but without knowledge and understanding of how shafts really work, it is not possible to select a shaft properly. Maybe it flies higher, or farther, straighter by sight, but maybe just is not good enough, maybe it has too much torque and low ball speed. If it is a swing fault that is causing a problem it must be identified, and preferably rectified, unless you have the instruments and software to aid in decision making. Spin is another critical aspect that must be a known factor. Too much or too little spin severely affects the ball flight, but by cutting the ball, increases side spin as does hooking. Golf is a dynamic sport and the shaft will flex and bow during the down swing rendering the result of static measurements useless.

Likewise playing an unsuitable ball will not aid your game, and by having a ball test where only one brand is offered, means little to anyone. It is essential that balls from all manufacturers are compared, and the golfer then can choose what price bracket meets his budget.

When taking a pilots licence it is essential that the pilot knows sufficient theory and can pass the practical exam, or people will die. Unfortunately there are not many skilled fitters with proper equipment to pass the theory and practical exams here, few with any measuring equipment, and hardly anyone with a launch monitor.

Since becoming associated with Hank Haney means additional training and testing on club design and fitting that making interesting comparisons to our existing knowledge.

Golf club design and manufacture are very important in head selection. The sole width and bounce are important in both swing type and conditions of the golf course. Many sets have stronger lofts and the ball is seen to fly and roll longer than another, but this is only because it is really a 5 iron head loft on a six iron shaft length. You will find these sets do not have long irons as they would be like hitting #1 and #2 irons. These clubs usually have cast heads that cannot have the lies and lofts adjusted, thus not being able to get even divits or correct the ball trajectory and direction. Cast clubs are made by pouring melted metal into a mould, that then contains air bubbles in the metal. The cooling process means shrinking metal. Some heads are made of alloys that would break if one attempted to bend them, while others are various hardnesses of steel. Molecules in the cooled heads are inconsistent and mixed with air. Hard spots and dead spots are a result and these will influence the ball speed and flight. Weight of individual heads are inconsistent and as a result lead weight is usually added to the hosel base to get some balance in swing weights within a set.

When taking a pilots licence it is essential that the pilot knows sufficient theory and can pass the practical exam, or people will die. Unfortunately there are not many skilled fitters with proper equipment to pass the theory and practical exams here, few with any measuring equipment, and hardly anyone with a launch monitor.

Since becoming associated with Hank Haney means additional training and testing on club design and fitting that making interesting comparisons to our existing knowledge.

Golf club design and manufacture are very important in head selection. The sole width and bounce are important in both swing type and conditions of the golf course. Many sets have stronger lofts and the ball is seen to fly and roll longer than another, but this is only because it is really a 5 iron head loft on a six iron shaft length. You will find these sets do not have long irons as they would be like hitting #1 and #2 irons. These clubs usually have cast heads that cannot have the lies and lofts adjusted, thus not being able to get even divits or correct the ball trajectory and direction. Cast clubs are made by pouring melted metal into a mould, that then contains air bubbles in the metal. The cooling process means shrinking metal. Some heads are made of alloys that would break if one attempted to bend them, while others are various hardnesses of steel. Molecules in the cooled heads are inconsistent and mixed with air. Hard spots and dead spots are a result and these will influence the ball speed and flight. Weight of individual heads are inconsistent and as a result lead weight is usually added to the hosel base to get some balance in swing weights within a set.

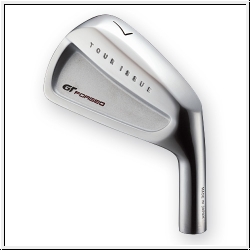

Forged heads are very much better, although many forgings are from China and Taiwan, the best establishments and workmanship are in Japan. Here clubs are crafted by craftsmen and not unskilled cheap labour. The forging process differs from flattening a round billet with one or 2 blows, to numerous hammerings from a massive air hammer in Japan, and sometimes the inclusion of pressed grooves. The steel quality used differs substantially and the price of these clubs indicates the expense of quality. The even distribution of steel and carbon makes for very forgiving clubs and consistant ball speed and flight. Lies and lofts can be adjusted easily and improve your scores and enjoyment of golf.

What you see when you look down at your club must appeal to you. Looks are very important in the game of golf.

The shaft transfers the energy created in your swing into ball flight. We measure that energy. The shaft flex, weight, kick point and torque amongst others are based on your swing speed, swing tempo and ability. The shaft must suit your swing precisely and the shaft must be trimmed and fitted into the club head with extraordinary care in order not to alter the shaft's characteristics or a club will fail to play as it should. No branded clubs are assembled with such care to detail and often you will see that the origin of the shaft is unknown and carries no manufacturer's logo or name. This is because the shaft is not manufactured by a reputable shaft manufacturer. The shaft also dictates one of the most important factors in a golf club, its overall length. Shaft technology has gone forward in massive leaps and bounds and with so many really good shafts on the market it is important to know which one is best for you.

The shaft transfers the energy created in your swing into ball flight. We measure that energy. The shaft flex, weight, kick point and torque amongst others are based on your swing speed, swing tempo and ability. The shaft must suit your swing precisely and the shaft must be trimmed and fitted into the club head with extraordinary care in order not to alter the shaft's characteristics or a club will fail to play as it should. No branded clubs are assembled with such care to detail and often you will see that the origin of the shaft is unknown and carries no manufacturer's logo or name. This is because the shaft is not manufactured by a reputable shaft manufacturer. The shaft also dictates one of the most important factors in a golf club, its overall length. Shaft technology has gone forward in massive leaps and bounds and with so many really good shafts on the market it is important to know which one is best for you.

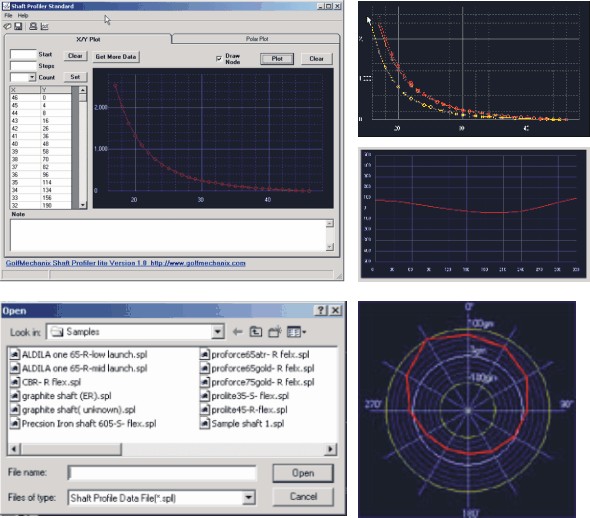

Shaft Optimisation System

We can optimise the performance of the shaft by as much as 20%. That is 20% more than if we carried out a normal shaft replacement.

I find the part of the shaft that is more resistant to bending than any other part. Flaws exist in all shafts; regardless of the material they are made from (steel, titanium, graphite, etc.) and regardless of the manufacturing process. The flaws in the shaft, caused by any number of manufacturing inconsistencies e.g. the shaft not being perfectly round or straight, being thinner or thicker at different points or maybe an imperfection in the shafts material. When a golf club is swung it is forced to bend; this flexed shaft will then naturally want to straighten and return towards its prominent flaw and will leave the clubface slightly open or closed on impact depending how it was set in the head. This will result in off centre hits, lost distance, inconsistency and a general feeling that the club is not working for you.

We align and install the shaft into the club head in such a way that it prevents occilation and works with your swing and not against it. To my knowledge, no club manufacturers supplying the mass market (regardless of their pedigree) are optimising their shafts, for a very simple reason, the process takes time and requires a skill level that does not lend itself to their assembly lines. If, when you acquired your golf clubs, the phrases, shaft orientation and FLO, and shaft optomised were not mentioned, it's a matter of luck whether the shafts in your golf clubs are positioned correctly and the club is performing as well as it should. As a professional club maker I want every club I build or rebuild to be the best it can possibly be and believe the process of shaft optomisation, will without question, give any club more distance and improved consistency.

An independent study on spine alignment was undertaken by Golf Science Consultants Inc, performed by J. Howard Butler, President of Golf Science Consultants, Inc, and former vice-president of shaft technology at True Temper, clearly indicated that when the golf shaft is properly aligned the club becomes more stable, improving the impact repeatability (more on centre hits). In all golfers tested impact repeatability improved from 14 to 51% when changing from non-aligned to spine aligned golf clubs.

Golf Digest recently reported on tests conducted by Dr. P. C. Chou of the Drexel University Ballistics Research Centre, which revealed that a player loses about six yards for every two-tenths of an inch they miss the centre of the club (the sweet spot).

Tom Stine, PGA Tour Partners Magazine. September/October 2002: "The bottom line is that if the spines are not set in the club heads at the proper angle in relation to the clubface, we are not getting the most out of our golf clubs and we will continue to have golf clubs that will perform differently than others. Did spine aligning my golf clubs make a difference? It sure did. I'm hitting my 8-iron, 9-iron and wedge further. I also noticed that I hit my woods straighter, and I don't hate my 6-iron anymore."

John Gordon, National Press, May 1999: "In auto-speak, no matter how good or expensive the tyres on your car, you won't get optimum performance if your wheels aren't aligned."

Harry Coffee, Fenwick Shaft's Director of Composites, March 2000: "having shaft spines aligned in the plane of the swing is better than having them haphazardly positioned in a set of golf clubs"

Golf International Magazine In its April 05 issue celebrating its 50th edition, Golf International Magazine put Shaft Alignment on its list of the 25 most essential equipment developments in 500 years of golf history and was included alongside Gene Sarazen's innovative sand wedge and the introduction of metal woods.

Do the tour pros have their shafts aligned?

Yes, the PGA and Champions tours in the States must have close to a 100% take up in this technology, with the Europeans and the rest of the World following behind. The next time you watch a Tour pro in action, take a close look at their graphite golf clubs and the location of the manufacturer's logos on the shafts. Chances are that they won't all be facing up, as they are on your golf clubs. Instead they'll be rotated to various positions, because their golf clubs have been spine aligned, the logos started out on top, but were moved when the shafts were rotated and re-aligned.

Can I have my shafts re-aligned?

Yes, regardless of whether you are having new golf clubs built or you are fine tuning your old equipment you can benefit from this technology.

We can optimise the performance of the shaft by as much as 20%. That is 20% more than if we carried out a normal shaft replacement.

I find the part of the shaft that is more resistant to bending than any other part. Flaws exist in all shafts; regardless of the material they are made from (steel, titanium, graphite, etc.) and regardless of the manufacturing process. The flaws in the shaft, caused by any number of manufacturing inconsistencies e.g. the shaft not being perfectly round or straight, being thinner or thicker at different points or maybe an imperfection in the shafts material. When a golf club is swung it is forced to bend; this flexed shaft will then naturally want to straighten and return towards its prominent flaw and will leave the clubface slightly open or closed on impact depending how it was set in the head. This will result in off centre hits, lost distance, inconsistency and a general feeling that the club is not working for you.

We align and install the shaft into the club head in such a way that it prevents occilation and works with your swing and not against it. To my knowledge, no club manufacturers supplying the mass market (regardless of their pedigree) are optimising their shafts, for a very simple reason, the process takes time and requires a skill level that does not lend itself to their assembly lines. If, when you acquired your golf clubs, the phrases, shaft orientation and FLO, and shaft optomised were not mentioned, it's a matter of luck whether the shafts in your golf clubs are positioned correctly and the club is performing as well as it should. As a professional club maker I want every club I build or rebuild to be the best it can possibly be and believe the process of shaft optomisation, will without question, give any club more distance and improved consistency.

An independent study on spine alignment was undertaken by Golf Science Consultants Inc, performed by J. Howard Butler, President of Golf Science Consultants, Inc, and former vice-president of shaft technology at True Temper, clearly indicated that when the golf shaft is properly aligned the club becomes more stable, improving the impact repeatability (more on centre hits). In all golfers tested impact repeatability improved from 14 to 51% when changing from non-aligned to spine aligned golf clubs.

Golf Digest recently reported on tests conducted by Dr. P. C. Chou of the Drexel University Ballistics Research Centre, which revealed that a player loses about six yards for every two-tenths of an inch they miss the centre of the club (the sweet spot).

Tom Stine, PGA Tour Partners Magazine. September/October 2002: "The bottom line is that if the spines are not set in the club heads at the proper angle in relation to the clubface, we are not getting the most out of our golf clubs and we will continue to have golf clubs that will perform differently than others. Did spine aligning my golf clubs make a difference? It sure did. I'm hitting my 8-iron, 9-iron and wedge further. I also noticed that I hit my woods straighter, and I don't hate my 6-iron anymore."

John Gordon, National Press, May 1999: "In auto-speak, no matter how good or expensive the tyres on your car, you won't get optimum performance if your wheels aren't aligned."

Harry Coffee, Fenwick Shaft's Director of Composites, March 2000: "having shaft spines aligned in the plane of the swing is better than having them haphazardly positioned in a set of golf clubs"

Golf International Magazine In its April 05 issue celebrating its 50th edition, Golf International Magazine put Shaft Alignment on its list of the 25 most essential equipment developments in 500 years of golf history and was included alongside Gene Sarazen's innovative sand wedge and the introduction of metal woods.

Do the tour pros have their shafts aligned?

Yes, the PGA and Champions tours in the States must have close to a 100% take up in this technology, with the Europeans and the rest of the World following behind. The next time you watch a Tour pro in action, take a close look at their graphite golf clubs and the location of the manufacturer's logos on the shafts. Chances are that they won't all be facing up, as they are on your golf clubs. Instead they'll be rotated to various positions, because their golf clubs have been spine aligned, the logos started out on top, but were moved when the shafts were rotated and re-aligned.

Can I have my shafts re-aligned?

Yes, regardless of whether you are having new golf clubs built or you are fine tuning your old equipment you can benefit from this technology.

This unique ultra modern equipment was designed by engineers for use by engineers. It is essential that the user has an engineering background otherwise this advanced equipment becomes a spine finder due to the lack of engineering knowledge to use it for the purpose it was designed for. It uses load rather than frequency and as you load a shaft in your swing why not use that load when building the club that relates directly to your swing. It detects shaft spines and enables correct orientation, is a flex sorter, and produces flex zone profiling using RS-232 Software Kit and Shaft Rotation Dial Indicator. Functions and features too numerous to list. This is a time consuming process, but well worth the cost and time. Once this process is complete and the shafts trimmed to the information acquired, and set into the heads, FLO is the next process. With the aid of a lazer we eliminate any sign of oscillation before the shafts set in the heads. The clubs are then left to set before the gripping process begins.